Description

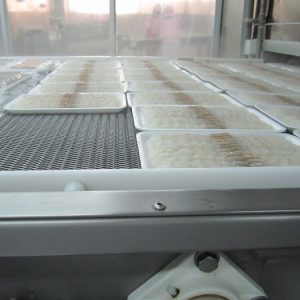

- Very long conveyor belt moves spirally in a circular cylinder, the conveyor layers move in a cascade.

- SAREE's Spiral IQF spiral conveyor is assembled from fully machined and assembled parts at the construction site, saving installation time, the entire frame structure is made of 304 stainless steel to ensure hygiene and food safety.

- The conveyor frame is placed on inclined surfaces to ensure no water stagnation during the cleaning process.

- The entire structure is surrounded by insulated panels assembled together to form a closed room, ensuring no heat loss to the outside and wasting energy.

- The conveyor frame is placed in the middle of the freezer room with large and airy aisles to make it easy to manipulate during cleaning.

- The feed inlet is directly connected to the conveyor frame, the frozen product is continuously passed through the cold air chamber by a spiral conveyor rotating around a fixed axis, the freezing speed depends on the size. and product characteristics.

- The control cabinet is located right at the conveyor belt to make it easy to operate, the cabinet is equipped with a PLC controller with an HMI interface. The control interface integrates the input product selection function to automatically control the parameters of conveyor speed, fan speed, chamber temperature suitable for each type of frozen product and can be fine-tuned during operation. motion.

Reviews

There are no reviews yet.