Specifications

- Product center temperature in/out: +10oC/-18oC

- Refrigerant evaporator temperature: -45oC

- Freezer room temperature: -38oC đến -40oC

- Fluid delivery method: fluid pump / effusion tank

- Refrigerant: gas NH3 or R22

- Defrost method: hot water or gas

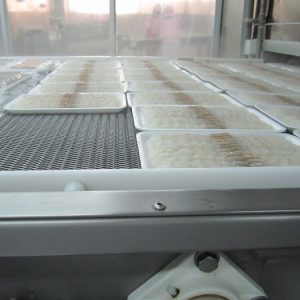

- Conveyor belt: mesh

Parameter table of IQF mesh conveyor belt manufactured by SAREE:

|

Model

|

Unit |

SA-BCTL500 |

SA-BCTL750 |

SA-BCTL1000 |

| Freezing capacity |

Kg/h |

500 |

750 |

1000 |

| Cooling capacity Qo needed |

KW |

110 |

165 |

220 |

| Conveyor material |

|

Stainless Steel |

Stainless Steel |

Stainless Steel |

| Conveyor Width |

mm |

1500/1800 |

1500/1800 |

1800 |

| Covering length (L) |

mm |

13900/10900 |

16400/13900 |

16400 |

| Covering width (W) |

mm |

3300/3550 |

3300/3550 |

3550 |

| Covering height (H) |

mm |

3200 |

3200 |

3200 |

| Feed Length (A) |

mm |

2000/2000 |

2500/2000 |

2500 |

| Voltage |

|

3Phase/380V/50Hz

|

Reviews

There are no reviews yet.